Oxymethylene Ether Catalysis Station

Continuously operated test stand

- Two solid catalyst systems can be tested in a continuous flow fixed bed reactor successively.

Use of molecular gaseous formaldehyde and water sensitive catalysts

- Molecular formaldehyde tends to polymerize in the presence of water and cannot be bought in gas bottles. Because of this, the gaseous formaldehyde is synthesized in situ by the decomposition of 1,3,5-trioxane and used instantaneously.

- The catalyst can be filled into the reactors in the absence of air. Therefore, oxygen and water sensitive catalyst can be used.

Continuous syntheses of Oxymethylene Ether

- Oxymethylene ether (OMEn) with the general formula CH3(-OCH2-)nO-CH3 (n = 3-5) are investigated as sustainable synthetic fuels for the use in diesel-vehicles. Because of the lack of C-C-bonds, OMEs burn without soot formation and can thereby reduce the formation of nitrogen oxides significantly.

- The continuous synthesis is based on the reaction of molecular formaldehyde with Dimethoxymethane (OME1) or Dimethylether (DME).

Analysis

- All gaseous starting materials and products are analyzed by online gas chromatography using an AGILENT 8890 gas chromatography system.

Oxymethylene Ether Catalysis – Batch Reaction Setup

- Semi-batch reaction of liquid Dimethoxymethane with molecular gaseous formaldehyde for the synthesis of Oxymethylene Ether (see: A. Peter, S. M. Fehr, V. Dybbert, D. Himmel, I. Lindner, E. Jacob, M. Ouda, A. Schaadt, R. J. White, H. Scherer, I. Krossing, Angew. Chem. Int. Ed. 2018, 57, 9461–9464).

- Molecular formaldehyde tends to polymerize in the presence of water and cannot be bought in gas bottles. Because of this, the gaseous formaldehyde is synthesized in situ by the decomposition of 1,3,5-trioxane and used instantaneously.

- The catalyst can be filled into the reactors in the absence of air. Therefore, oxygen and water sensitive catalyst can be used.

- With the use of Ionic Liquids, the homogeneous catalysts can be immobilized in a biphasic approach (see: A. Peter, G. Stebens, J. F. Baumgärtner, E. Jacob, F. K. Mantei, M. Ouda, I. Krossing, ChemCatChem 2020, 12, 2416–2420).

Four Channel Catalyst Testing Plant (funded by BMBF project BioMeOH)

- Up to four catalyst specimen can simultaneously be reviewed in fixed bed reactors with varying pressures (up to 40 bars), temperatures (up to 300 °C) and CO/CO2/H2 gas flows. All products will be online analyzed by a state of the art gas chromatography system (Agilent GC 8890, funded by BMBF project BioDME).

Single Channel Catalyst Testing Plant & Online Gas Chromatography

- In use for longtime and bigger scale analysis, the one channel testing plant is connected to an Agilent GC 6890N gas chromatograph. Temperatures (up to 300 °C), pressures (up to 40 bars) and feed gas (CO, CO2, H2) can be varied in a wide range.

Semi-automatic Precipitation Unit

- Powered by a HiTec Zang LabManager and LabVision system, semi automatic co-precipitations with up to four solutions can be executed in either 1 L or 6 L scale.

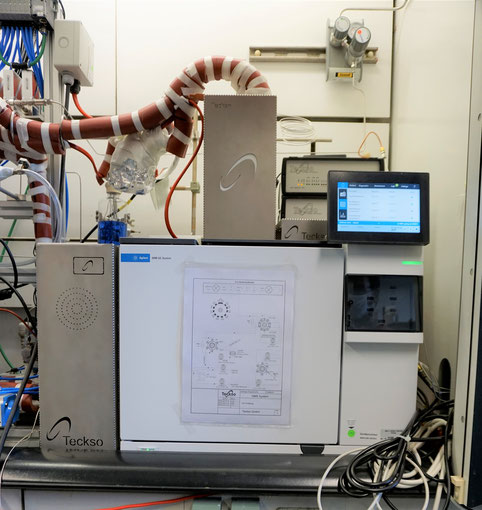

Online Gas Chromatograph (funded by BMBF project BioDME)

- The state of the art GC system GC 8890 from Agilent is able to separate H2, N2, O2, CO, CO2 from H2O, Methanol, Dimethylether and carbohydrates over a column system consisting of four columns. Quantification with two TCDs and a FID allows to analyze compounds even from 1-50 ppm scale.

Spray Dryer

- The Büchi Mini Spray Dryer B-191 dries precipitate from the semi-automatic precipitation unit (Lab Scale) into dry powder.

DRIFT-Spectrometer

Setup

- DRIFTS allows the measurement of the diffuse reflection of a strongly scattering or absorbing sample, typically powders and rough surface solids. The IR beam is focused on a sample by a special setup of paraboloid mirrors, the so-called praying mantis by Harricks. After the interaction with the sample, the diffuse reflected radiation is collected and transferred to the detector. Additionally, the optical system is equipped with a high-temperature reaction chamber that allows measurements at pressures of 10−2 mbar up to 32 bar and temperatures up to 900 °C. Four different gases are connected to the chamber (N2, CO, CO2 and H2) and the outlet gas steam is connected to a gas chromatograph to qualify and quantify reaction products.

Analysis

- In-situ measurements of solid catalyst systems can be tested during a continuous flow of gaseous reactants to investigate adsorbed reactants and intermediates on the catalyst surface (chemisorption and physisorption). The shape, compactness, refractive index and absorption of the particles are characteristic of the material. In order to evaluate the measurements, the spectra are plotted in units of Kubelka-Munk units, which makes the intensities proportional to the concentration.

Methanol synthesis

- Current research on DRIFT spectroscopy is the methanol synthesis out of H2 and CO2 on different catalyst systems. Chemisorption and physisorption measurements can provide insights into the reaction mechanism and the active sites.

Chemisorption

- With a TPDRO 1100 from Porotec gas ad-/desorption, reduction or oxidation experiments in dependence of temperature can be carried out.