Subgroup Catalysis - Energy Conversion and Storage...

From CO2-Hydrogenation to Methanol, Dimethylether and Oxymethyleneethers

Being a convinced thermodynamics guy, our approach to convert and store fluctuating energies in chemical bonds started with an analysis of the thermodynamic relations of the underlying reactions. And clearly, 'Ionic Systems' do play a role...!

The following molecules turned out to be relevant according to the analysis.

A possible thermodynamic network of reactions delineating the synthetic options are given on the next figure.

Thus, in our subgroup we set out to find sustainable catalytic pathways to convert carbon dioxide and hydrogen first into methanol. Since this conversion is exothermic and at standard conditions even endergonic, the coupling to an exothermic reaction like the dehydratisation of two molecules methanol to give dimethylether (DME) appears useful. Since DME is a gas, also further conversion to the Diesel-substitute and liquid OME appears sensible.

Catalysis for Methanol Synthesis...

Today’s methanol is produced from fossil fuels by catalytic hydrogenation of a mixture of much carbon monoxide and little carbon dioxide. A more sustainable way to produce methanol would be to use only carbon dioxide as C1 source and hydrogen derived from water electrolysis. As a result of carbon dioxides stability, this reaction is thermodynamically less favored (∆rH298 = −49 kJ mol–1 compared to –91 kJ mol–1 from CO) and hence harder to achieve in sufficient space-time yield than via the syngas process for commercial purposes. The industrially applied syngas methanol catalyst is Cu/ZnO/Al2O3, in which the Cu/ZnO “synergism” is operative. Although this catalyst system is also suitable for CO2-hydrogenation, its performance decreases significantly below 210 °C due to deactivation by water (it ‘drowns’, since in the CO2-route water is produced quantitatively).

We work on two sides to over come the limitations: Improve the supports to make the system more tolerable towards water (i.e.: a Cu/ZnO/ZrO2 system in ChemCatChem 2014, 6, 1721-1730). In addition, the Cu/ZnO “synergism” may be optimized by oxidative fluorination described below (Angew. Chem., Int. Ed. 2019).

Fluorinated Cu/ZnO Catalysts: Upon fluorination of our benchmark Cu/ZnO catalyst system, additional ZnO1-x defect sites were introduced that led to an increased number of active sites for MeOH catalysis, but increased the activation energy for the competing reverse water gas shift reaction. Thus, also the selectivity for MeOH synthesis increased. Starting point for novel catalyst systems…!

F-Cat: Angew. Chem., Int. Ed. 2019.

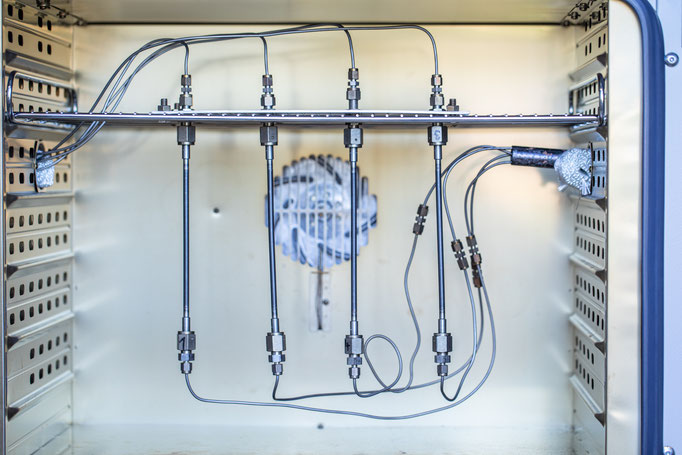

Catalysis Test Station

The gallery on the right gives some impressions on the catalysis set up used in our catalysis laboratory situated in the bulidung of the Freiburg Materials Research Center FMF.

To understand the mechanism of methanol formation, we established a series measurements including DRIFTS-spectroscopy (se up left), rather detailed TPDRO-investigations as well as kinetic investigations.

The experiments are complemented by quantum chemical calculations performed independently or in collaboration, as shown in the next entry.

Mechanistic investigations: Together with the Group of Prof. M. Moseler and M. Walther, we investigated the mechanism of MeOH formation by periodic DFT calculations and for the first time investigating the transition state energetics with molecular cluster calculations at the CCSD(T) level. According to this investigation, the the DFT barriers are by roughly 1/3 lower than those assessed by ab initio theory. The structural cluster model using a Cu4(ZnO)3 molecule as catalyst model, had prior been shown to perform the catalysis inside a mass spectrometer.

With T. Reichenbach, M. Walther, M. Moseler:

J. Catal. 2018, 360, 168-174.

Catalysis for OME-Synthesis...

As a basis for this work, we were performing a full thermodynamic Evaluation of the Reaction Network: Sustainable Energy & Fuels 2017, 1, 1177-1183 (see Figure above).

Together with our partners at the Fraunhofer ISE, we devised a Vapor-Liquid-Equilibrium Model to understand and model possible routes to OME. Vapor-Liquid-Equilibrium Model: React. Chem. Eng. 2017, 2, 50–59.

In this work we also devised a direct and energy efficient anhydrous route to OME by using molecular formaldhyde (FA) obtained dehydrogenation of methanol.

By contrast to published anhydrous routes through the use of trioxane (as FA substitute), up to 87 % of the energy may be stored in the product (Figure right, only 67 % for the

Formox/trioxane-route).

Sustainable catalysis to Oxymethylenethers (OME). The route devised in React. Chem. Eng. 2017, 2, 50 was established for a batch process using OME1 as a model substrate: Angew. Chem., Int. Ed. Engl. 2018, 57, 9461-9464. Here the WCAs of our group were again helpful: Only with the counterion [Al(ORF)4]– (RF = C(CF3)3) the O(CH3)3+-catalyst was active enough to catalyze the conversion without solvent only in the OME1 subtrate.

Reusable and easy to separate: In a new biphasic reaction, OMEs may be

synthesized from dimethoxymethane (OME1) and gaseous formaldehyde in a homogeneously catalyzed process. The immobilization of the molecular

OMe3+-catalyst in an ionic liquid enables facile catalyst separation / reusability and delivers very pure OMEn-mixtures. Now also commercial

OMe3+[BF4]– catalyst may be used, facilitating application.

OME Synthesis: Catalysis Test Station

Currently we are constructing a continous catalysis test station for OME-synthesis from DME / OME1 and formaldehyde. Some impressions are shown in the gallery right.